Technology Demonstrator

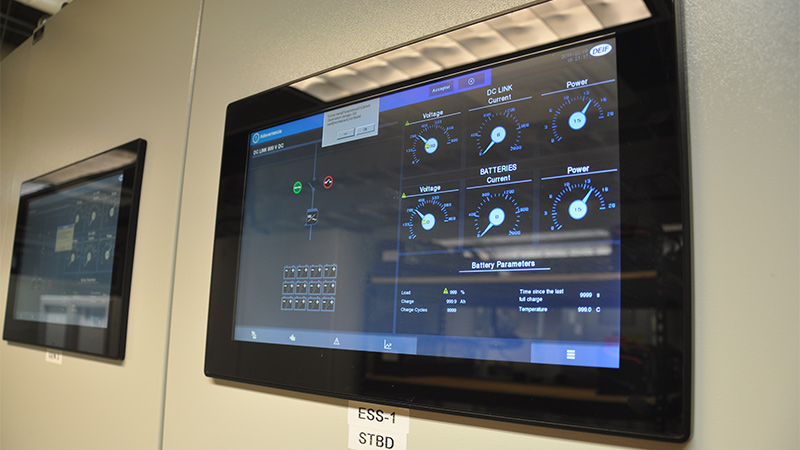

Ockerman Automation is managing the conversion of the vessel performing the necessary upgrades and engineering. When complete the vessel will expand the capabilities of the Marine Electric Propulsion Simulation Laboratory (MEPS). It will also provide a platform for the analysis of the technology to be proven on board a high-speed surface vessel.

Customers can go aboard the technology demonstrator to see our solutions in action and then visit the MEPS Lab to see the integrated solutions for their own vessels designed, modeled, and operational in the state-of-the-art simulator. This asset along with the MEPS Lab will provide customers with a design experience unrivaled in the industry.